Since the end of the 1960s-1970s, in an extraordinary momentum produced by the birth of the "studio-glass" movement in the USA and in Europe, passionate artists in search for new expressions, give a new start to an age-old.art, with a return to handicraft structures.

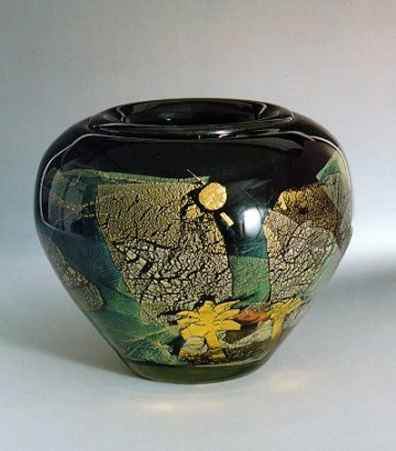

In our days , a French glass blower like Jean-Claude Novaro has become a star in glassblowing . Novaro creates worlds overloaded with heat an light ; the glass processed is pure, thick and heavy. He is one of the scarce artists capable to glass blow pieces which are over 20 pounds (10 kilos). His ability to obtain enamals and oxides to the suitable shade and at the precise place where it has been projected, demonstrates how well he masters the material. He continually improves his artistic capacities.

In our days , a French glass blower like Jean-Claude Novaro has become a star in glassblowing . Novaro creates worlds overloaded with heat an light ; the glass processed is pure, thick and heavy. He is one of the scarce artists capable to glass blow pieces which are over 20 pounds (10 kilos). His ability to obtain enamals and oxides to the suitable shade and at the precise place where it has been projected, demonstrates how well he masters the material. He continually improves his artistic capacities.

Technique

In the past, glass used to be melted in open air furnaces, then the technique gradually got ameliorated.

In those for off time, glass used to be fashioned in various techniques.

Rolling up molten glass on baked clay kernels.

Melting coloured sticks.

The envention of the blowpipe in the first century B.C, made it possible for glass to be fashioned through the blowing process.

Very Malleable under heat, it falls in with various shapes.In the melting pot of the furnance glass is melted to rearly 1200°, previonsly the composition should be carefully checked as well as the viscosity of the paste before being processed.

Glassblowing unplies serveral steps

Thanks to blowpipes, the master glazier or assistant takes a sample from the mething pot, molten glass have a honey like colour and viscosity, this operation is called "picking" ; then glass is rolled up on a marble sheet in order to have it centred perfectly and have it fashioned with a water drenched wooden beetle.

After "marbling" the master glassblowing at the other end of the pipe and them achieres a "post".

This operation is renewed after successive reheating to shape and develop "the paraison" i.e. the final quantity of molten glass required to create a work. Open an glass blowing is performed by varying the position of the pipe in space by holding a constant and regular rotating movement.

As a complement to glassblowing, glass fashioning under heat needs other gestures and diverse tools such as the "pontil" to pick up glass irons helps you to open and design the shape, scissors to trim it.

Application of glass strings

The master glass worker adds an element under heat to the glass that was fashioned before, this decoration could be a plain string combined to enamels, or a glass string more or less thick displayed on a rotating plan and gathered under heat.

This technique allows Jean-Claude Novaro, to glass blow shapes for example the application under heat of a glass string on a vase or a figurative sculpture such as the ″clown″.

Iridescent glass

The irisation surface method is more often practised by glassblowers by heating in a reducing context a pre-fashioned object, to produce a reaction to the metal components previously included in the composition of the paraison*.

The other method is probably the ″fumage″ (a smoked-based process) of the object with steam coming from pewter or silver that have been previously set in a pot with an open lid, while the object is kept inside up to the suitable irisation

(iridescence).These metallic salts, melt to distilled water or alcohol, could directly be vaporized on the piece, during the under heat process.

*Paraison some external decoration varnish.

Multi-coated glass overlay

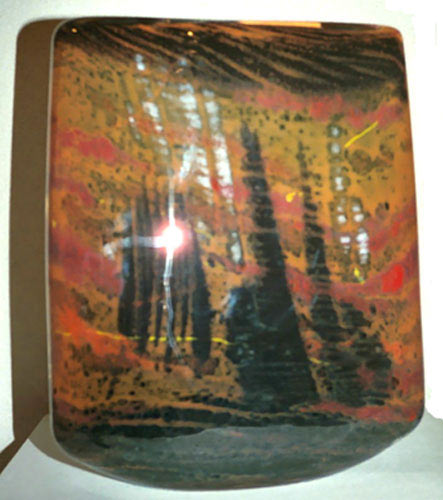

The works of Alain and Marisa Begou, objects in glassblowing overlay in 3 or 4 layers, reflect all the passion and pleasure of a constantly renewed style, theirs.

Like a poetic spark, the vivid colours used by the artists lighten a hormonizing ceration, owing its strenglh to the weight of glass in several layers, deautiful in aquiet beauty.

The nikname "overlay" describes glass carved made of many glass layers in various colours, these layers need to be frequently carved or engraved, bumps and hollows in order to express the different sabjacent colours.

Two inverted methods can be used to achieve that result. Either the glass blower dips the object with the chosern lint into a melting pot under heat with another shaded colour which gets incrusted artisde of the initial layer and recoversit.

This is the oldest technique and it is called "dipoverlay" or "flashing".

Or the master glassblower a glass paraison in glass inside where a thin layer in a contrasted colour and this technique is colled "cup overlay" or "cased glass".

We therfore can multiplify colour layers according to the artist's desire by repeating the operation.

Alain et Marisa Bégou - The various stages

Alain et Marisa Bégou - The work in progress

Alain et Marisa Bégou - The final work before oven of recuiss

See more videos of Alain and Marisa Bégou